Jill asks: What is the best roofing product to use on a carport and pergola? The carport roof covers both, which are part of the same structure. I am aware that there are plastic-coated steel sheets, polyester-coated, zinc, and polycarbonate sheets. It’s a minefield. There are lots of trees overhead, so everything goes green including the roof and patio. I was thinking of maybe going for a dark green-colored roofing product. What do you think? Kindest Regards

Steve Bliss, of BuildingAdvisor.com, responds: You are right that there are a lot of options for roofing a carport and similar structures. Assuming that you want to keep all the trees overhead and that everything will “go green,” then you are wise to go with metal or plastic roofing. These are certainly easier to clean than shingles, tiles, wood, or other materials. Also moss and lichen will shorten the life of asphalt or wood roofing materials and could have a similar effect on lower-cost metal roofs by trapping moisture against the roof surface.

Metal Roofing Options

A good quality metal roof will outlast plastic, but each has its pros and cons. As you noted, there are many options to choose from for both metal and plastic. Not surprisingly, the most expensive options will last the longest.

With metal roofing, the type of metal, its thickness, and the quality of the paint will determine the lifespan of the roof. Typical low-cost steel roofing has a light galvanized layer and, if painted, uses polyester coatings. A step-up would be silicone-modified polyester (SMP) paint.

Getting green-colored roofing to match the debris and mold/moss/algae sounds reasonable if you plan to let things grow on the roof. If you go with a pre-coated steel roof, choose a smooth finish as this will be easier to clean than a textured coating. Also be aware that the finishes used on inexpensive metal roofing will lose their luster in a few years.

Unfinished metal roofing is another option. Copper would be great because it will naturally inhibit the growth of mold and algae, and it will turn green over time from oxidation. But it is one of the most expensive roofing materials you can buy. Galvalume roofing is another option that is much less expensive and will inhibit growth to some extent because of the zinc in the galvanized coating. Aluminum is another long-lasting and durable metal, but does not have the anti-mold properties.

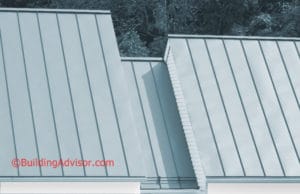

Corrugated sheet metal products are much less expensive than traditional standing-seam metal roofing and easier to install. They were originally developed for agricultural and utility buildings, nut are not marketed to the housing market as well, and would be a good choice for your application.

Corrugated Plastic Panels

Plastic corrugated roofing is another inexpensive option that might be suitable for a carport.

In general, high quality plastic panels – polycarbonate or fiberglass (FRP) — will be more expensive than cheap metal roofing, but less expensive than premium metal products. I would avoid PVC and acrylic panels as they are not very durable.

Plastic panels are stiffer and easier to install than metal, but less durable overall than premium metal. They are more prone to damage from hail or stray baseballs, and from damage during installation. Also, they are not recommended in hot, sunny climates. Thermal expansion can cause damage around screw holes and can warp thin, corrugated plastics. As with any building material, thicker panels will be stronger and more durable than very thin ones.

In general, polycarbonate is stronger than FRP and more resistant to impacts and chipping, but scratches easily and will show dents. Some polycarbonate panels have a UV-resistant film that will prolong their life span. Polycarbonate is available in a single-wall corrugated sheets or more expensive double-layer “twinwall” configuration popular for greenhouses.

Most plastics are translucent, which might be good for a pergola or carport where light is welcome. But you can also see debris, bird droppings, and dirt build-up. Some can be walked on; others can support very little weight. Some have a smooth surface that will be easier to clean than those with a textured surface. Many have anti-scratch or UV coatings that will help with their appearance and longevity, but they are still are prone to scratching. For a pergola or carport, plastic roofing is a good choice, but I wouldn’t recommend them for prime living space.

With any metal or plastic panels, installation details are critical as they need to allow for expansion and contraction of the materials without creating leaks or damage around the screw holes. Also, pay attention to the cleaning recommendations as some types of chemical cleaners or abrasive scrubbing may harm the panels. Also look at warranties. Roofing warranties are usually for materials only and are pro-rated, so they are not worth a whole lot but give you some idea of how much confidence the manufacturer has in the materials. Along those lines, carefully follow the manufacturer’s recommended installation details or any warranty protection will be lost.

Mark C Jenkin says

Polycarbonate Roofing Over Firepit?

Hi, I’m looking to put a gazebo over my firepit area. Going to do a double roof so the smoke can go out the top. My plan was for a metal roof for the safety of not caching fire. I’ve seen the polycarbonate ones and have been considering them because of the of the cost and that they let light through during the day. I don’t have big roaring fires. Just a normal size. Maybe a couple of feet high at the most. Would the polycarbonate roof panels be safe over the firepit? Also, I have read that the polycarbonate panels are good for 2″ of snow and 30 mph of wind. The metal said 3″ of snow and 40 mph of wind. I live in CT and quite often get winds in the 30-40 mph with gusts higher and snow in the 5″-10″ range. I have had snow up to 23″. Are these numbers conservative or do I have to worry about the winds and snow? Thanks.

buildingadvisor says

In general, metal roofs are stronger, more durable, and more heat-resistant. Somewhere around 250 – 300 degrees F, polycarbonate panels will start to deteriorate and deform. So plastic panels of any type wouldn’t be a great choice over a firepit.

Metal will also handle wind and snow loads better. The published numbers tend to be conservative and include a safety factor, but it’s never wise to push the limit with building materials. The exact limits will depend on the spans between supports and type and spacing of fasteners.

Over time, polycarbonate tends to yellow and show scratches and dirt, while metal is prone to corrosion. However metal roofing is easier to clean.

With the smoke and heat of a firepit, I don’t think plastic would be a good choice.

One option would be to combine the two: use metal panels in the hot zone and translucent panels as skylights away from the heat.

Abhijit says

Recommended Thickness For Polycarbonate Roofing Panels?

Thank you very much for this great write-up! It’s been extremely helpful while trying to make sense of different options.

For our purposes metal is out because of noise concerns in a nearby bedroom. You’ve suggested a “thick” Polycarbonate roof to withstand hail – What would be your minimum recommendation? On another site I saw 10mm, would that be sensible?

buildingadvisor says

Not sure what the polycarbonate panels being used for — or whether you are using flat, corrugated, or twinwall sheets.

With corrugated material on a carport, patio, greenhouse, or other accessory structure, you would want a thickness of at least 6-10 mm. For a permanent structure such as a conservatory, you may want a thicker panel. With twinwall material, 6 mm is the most common, but 10-16 mm will provide better long-term performance. Twinwall panels have a honeycombed structure providing greater stiffness.

In general, thicker panels are more durable and able to span greater distances between supports. Make sure not to exceed the maximum span recommended by the panel manufacturer

Mike Parenteau says

Excellent, nonpartisan advice–thanks!

Shanda says

Is Dark PCV Hotter than Clear?

Will darker opaque vs clear pvc corrugated cause the enclosed space to become hotter than the latter? I’m enclosing my deck for my cats leaving the roof open…

buildingadvisor says

In general, dark surfaces absorb more light and heat than light-colored surfaces and get hotter. This is especially true for horizontal or sloping surfaces such as roofing or decking. That’s why “batch” solar water heaters are painted black, not lighter colors.

I’m not aware of any data on plastics, but extensive research by the Florida Solar Energy Center has shown that reflective, white, and light-colored roofing lowers attic temperatures and reduces cooling loads compared to dark shingles. The numbers varied depending on the reflective quality of the roofing surface.

So light-colored or white panels would be your best choice. Clear panels will let light and heat pass through the plastic into the enclosed space, but tend to trap the heat — the so-called “greenhouse effect,” which heats up passive solar homes. How much heat it transmits and traps will depend on its solar transmittance, which varies from one product to another.

Dale Carpenter says

Can Metal Roofs Withstand Hail?

My contractor replaced corrugated polyvinyl panels on my deck roof after two bad orange- to grapefruit-sized hail storms in one month . The prior corrugated panels were fiberglass and had been on for around 35 years. The new polyvinyl lasted less than a year after a minor hail storm with Quarter sized hail. I want to put metal corrugated panels that match the polyvinyl, on top of the existing polyvinyl panels. I talked to several people familiar with the panels that said it should be alright to do it. Can you give me information as to pro or con advice ?…Thank You..

buildingadvisor says

I agree that placing the new metal panels over the existing plastic roofing is OK as long as the corrugated patterns line up. Having two layers will give you a bit more rigidity in roof surface. Maybe it will help the roof withstand the next grapefruit-sized hail storm.

With the size of hail that you are experiencing, you can expect to get some denting in a metal roofing. Most metal roofs can withstand hail, but with your icy baseballs, oranges, and grapefruits, you would be wise to go with a heavy- gauge metal. In general, metal roofing is the strongest choice for corrugated roofing. Downsides including noise during rain (or hail), color fading, and rust if you do not choose a corrosion-resistant material and premium baked-on finish.

There are many choices. If you are in a coastal area, you should consider a material like Galvalume or aluminum for the roofing material. Aluminized steel would also be a good choice. Plain galvanized steel is your least expensive option and will probably need to be repainted every five to 10 years depending on the paint type and local conditions.

Mark says

PVC vs. Polycarbonate or Colorbond Roofing for Carport?

For a cantilever carport I’ve been told PVC vinyl will handle hail, which is a bit hard to believe let alone big gum tree branches. Would polycarbonate or Colorbond metal do better? Please advise.

Thx

buildingadvisor says

PVC and acrylic panels are your least expensive option, but also the least durable. Thicker PVC panels might handle the hail, but can warp in high temperatures. High-quality, heavy-gauge polycarbonate panels with UV-protection should tolerate moderate hail, but I’m not sure about tree branches. Also, it is prone to scratching and denting. For durability and longevity, Colorbond steel panels would be your best choice. Colorbond is a proprietary baked-on coating widely available in Australia. It has anticorrosive properties and has established a good track record. Performance should be similar to and Kynar- or Hylar-coated panels in the U.S.

Jill says

Will Metal Roofing Make Patio Hotter?

Will corrugated metal roofing on an 8-ft tall patio make it hotter than other roofing materials? We live in a tropical climate where it is hot and humid for the majority of the year.

buildingadvisor says

Corrugated metal roofing will outperform many other roofing systems in hot weather as long as the top surface is white, either factory-painted or painted by the owner. The roofing will perform even better if the bottom surface is coated with aluminum paint or an equivalent low-e (low-emittance) coating. Most shiny metallic coatings will emit very little heat.

The white paint on top reflects a significant percentage of the solar heat that strikes the roof surface as visible light. The low-e coating on the lower surface further reduces the radiant transmission of heat into the space below.

For the purpose of heat reduction, this is one of the most effective low-cost roof choices for many building types, including carports, patios, and utility buildings in hot climates.

Cory says

Can I Use Corrugated Roofing Under a Deck?

I have a walk-out basement with a patio underneath the deck. Was looking for an inexpensive option to keep the patio below the deck dry. Are all of these corrugated roofing options okay for an application like that?

buildingadvisor says

Yes, corrugated plastic (or metal) roofing can be adapted to create a dry space below the deck.

There are a variety of commercial systems for underdeck drainage, or you can make your own system with corrugated roofing or heavy waterproof sheeting such as EPDM.

How dry the space is below depends on how much trouble you want to go through with the details. For a completely dry area, you’ll need a flashed connection at the wall and a guttering system at lower end of the drainage system. You may also need to flash around deck support members if they get in the way of your drainage system.

Another issue is leaf debris and pine needles that get through the gaps in the decking and collect on top of the roofing or drainage material. Over time, this can build up to dense mass of leaf litter like you find in gutters with trees overhead. It’s best to leave access to flush the system periodically with a hose.

I have built a couple of systems with corrugated roofing and it worked well. In one case, it attached to the joists above, with spacers to create a slope. In the other, it attached to a separate roof structure below, which was part of a storage shed below the deck.

Read more on Underdeck Drainage System and find links to system manufacturers.

DaveK says

Adequate Slope Needed for Underdeck Roofing

Another issue to consider when building a “roof” below your deck is to maintain the minimum pitch to prevent water bleed-back at the panel overlaps, and making sure it is well-flashed where the roofing meets the house walls.

Minimum pitch on corrugated roofing is 3:12 (IRC-International Residential Code), and keeping your deck reasonably level above this can be a challenge. Membrane roofing can go down to about 1:12, and sometimes lower if carefully installed. It’s also easier to flash to the house walls.

lloyd bell says

Hello, I built a firewood rack 8′ X 16′. I plan on having 4″x4″x16′ pressure treated beams run the long length at the front and back of the rack (so 8′ span). Will the polycarbonate panels be strong enough to survive an 8′ span? Would metal be better? Will I have to install a center beam at 4′ in order to handle snow in the Northeast? I have been told that I wouldn’t need to by a builder but I’m questioning the longevity of such a long span over time. Thanks,

buildingadvisor says

In general, metal roofing is stiffer than plastic and can probably span a greater distance. The actual span limit is going to depend on the thickness of the panel, panel style, and material. For example, polycarbonate comes as both corrugated panels and “twinwall” sheets.

That said, the standard approach to installing nearly all metal and plastic panels is to support each panel every 24 inches with purlins or solid bridging placed horizontally across the panels. The supports start at the eaves and end at the ridge. This type of support is especially important with snow or wind loads. Also, the lower the slope, the greater the snow load.

Unless the panel manufacturer publishes specs showing other installation details, I would follow this approach. If you can’t find the manufacturer’s website for the specific panel you are using, you can find a lot of examples online by Googling “corrugated plastic/metal roofing” and then click on Images.

Here’s a typical installation guide.

Best of luck with your new firewood rack!

Jaque Christo says

Metal Roof More Durable Than Plastic

I think having a metal roof sounds more durable and less maintenance-heavy than a plastic roof. Especially in the area I’d be putting the shed, I need the roof to handle multiple elements and stay strong. I’ll have to do some more research on whether the type of metal I use would make a difference and the exact costs. Thank you for the information.