In This Article

Interior Vs. Exterior

Type of Foam

Installation

Subslab Insulation

Subslab Vapor Barriers View all Foundation & Sitework articles

Basement wall insulation is recommended in most of the U.S. except for the deep South. Energy savings are about the same whether you insulate on the interior or exterior. The best insulation to use is rigid foam, which is largely unaffected by moisture. There are some small theoretical advantages to insulating on the exterior having to do with thermal mass, but these are far outweighed by practical concerns.

INTERIOR VS. EXTERIOR FOAM

In practice, insulating on the interior is usually a better option. The main advantages are:

• Exterior foam insulation is often damaged during backfilling, and is difficult to protect above ground. There are a number of protection systems, but most get damaged over time.

• Exterior foam provides a perfect entry point for termites and carpenter ants, as well as a comfy home for carpenter ants who like to hollow out the foam for nesting. (In termite-prone areas, you may be required to leave an “inspection gap” at the top of the wall with either interior or exterior foam.)

• Interior insulation is easier to install and usually results in a better overall job. In retrofits, it is often the only option. Also, the foam board helps keep moisture on the exterior and prevents condensation on the interior.

TYPES OF FOAM

Use either extruded polystyrene (XPS) such as Styrofoam or Foamular or expanded polystyrene (EPS), sometimes called “beadboard.” EPS is less expensive and rates about R-4 per inch vs. R-5 for XPS. However EPS is more permeable to water vapor and more prone to absorb water. Both types of foam need to be covered by drywall or another code-approved fire barrier on the interior.

EPS foam is available in different densities and the higher-quality products are stronger and less permeable to moisture, making them a better choice for basement applications.

Because of its low permeable, XPS on the interior helps keep moisture out of the finished space if the foam panels are well-sealed at seams and perimeter joints. On the the exterior, XPS foam is the best choice because it absorbs little water compared to EPS. Also XPS is stronger and better able to withstand backfilling.

Another good choice for interior basement insulation is foil-faced polyisocyanurate (iso-board), such as Thermax, with an R-value of about 6.5 per inch. You may be allowed to leave foil-faced insulation uncovered – check with your local building department. However, iso-board will readily absorb water so is not recommended for basement exteriors.

Spray foam is also an option on the interior, but is usually a lot more expensive than foam boards. and more difficult to finish.

When using foam insulation on basement walls, the building code (IRC) requires R-5 for southern states (excluding the deep South) and R-10 for the rest of the US. Many energy experts recommend R-15 to R-20 for far northern states. Estimated savings for R-10 insulation range from $250 in Washington DC to $400 in Minneapolis. You’ll also have a much warmer and dryer space, which may be the more important reason to insulate.

FOAM INSTALLATION

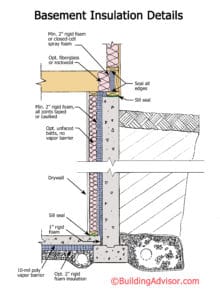

Place the foam board directly again the concrete or block and secure it with adhesive or concrete fasteners and washers. Make sure you use an adhesive formulated for use with foam board. For mechanical fastening, Plasti-Grip PMS fasteners work well for both concrete and block.

Seal the foam boards together with canned foam or a high quality building tape such as Dow Weathermate Construction tape or Dupont Tyvek tape. Also seal the foam at top, bottom, and corner joints with a small bead of canned foam. For a job this large, buy the large cans and a professional quality applicator gun – you’ll be happy you did.

If you are planning to finish the basement, you can use fewer fasteners and help hold the insulation in place with furring strips nailed through the foam or 2×4 studs, which provide nailing for the drywall and a space for wiring.

If you are adding studs, you can place unfaced fiberglass or rock-wool batts between the studs for added insulation. Because the added cost is modest, this a good idea in cold climates — as long as you have a very dry basement. If you’re not sure, best to leave out the fiberglass. If but could contribute to moisture or mold problems long-term.

No Vapor Barrier in Wall. Whatever approach you take, do not use a vapor barrier anywhere in the wall as it will do more harm than good, Basement walls need to dry toward the interior, so a low-perm vapor barrier under the drywall, such as plastic sheeting, can potentially trap moisture and promote mold and mildew growth. With foam board insulation, painted drywall provides an adequate vapor retarder.

SUBSLAB INSULATION

If you are planning to finish the basement space, you should also consider adding a layer of foam insulation below the slab. The insulation may not save much money in energy bills due to moderate earth temperatures at that depth, but it will warm the floor surface enough to reduce condensation.

Without insulation, water will condense on the cool surface of the slab in warm, humid weather. The damp slab causes musty odors and can damage floor coverings, finishes, and materials stored in the basement. This is especially problematic with carpeting on the slab. A warm, dry floor will greatly improve the quality of the finished space.

Two-inch extruded polystyrene foam (XPS) is typically used as one-inch foam is too fragile to place under a slab. Expanded foam (EPS) is a less expensive option, and considered better for the environment, but you would need to use high-density Type II EPS for this application. Type II foam has a nominal density of about 1.5 lbs./cu. ft.

It is possible to place the insulation above the slab in a retrofit. There are two main approaches:

- Place 2x4s flat on the slab and insulate between them. The 2x4s can “float” or be secured with concrete nails or Tapcons. Then nail subflooring to the 2x4s.

- Place 1 to 2 in. of rigid foam insulation on the slab and float the subflooring above. Float two layers of min. 1/2 in. insulation above the foam, staggering all joints. Secure the top layer of plywood to the lower layer with nails or screws.

If there is no vapor barrier below the slab, or you’re not sure, it’s best to add a vapor barrier on top of the slab, under the insulation.

SUBSLAB VAPOR BARRIERS

It’s important to add a heavy-duty vapor barrier under the slab to create a barrier to water vapor, which can readily pass through the concrete. The water vapor will harm any paints or floor coverings placed on the slab and can add significantly to household moisture levels.

The plastic sheeting use for the vapor barrier should be at least 10-mil thick unless you are using one of the reinforced plastics approved for this application. It is easy to damage a thin layer of standard poly while prepping for and placing the concrete.

The placement of underslab vapor barrier has been debated heavily in the concrete industry for two decades. The current consensus within in the concrete industry is that, when a vapor barrier is used, the best location is directly under the slab.

The problem is that the vapor barrier slows the drying of the wet concrete, extending the bleed time and finishing time, and sometimes leading to curling of the slab edges. Curling is a result of the top of the slab drying more rapidly than the bottom.

For years, many industry experts recommended placing a layer of sand or gravel above the vapor barrier to absorb bleed water and, thereby, reduce the finishing time and curling. However, this was found to cause more problems than it solved. Water was trapped in the sand or gravel “blotter” for extended periods, leading to high moisture levels in the slab and basement — causing the very problems the vapor barrier was intended to solve. Placing the vapor barrier below the insulation creates similar problems by trapping water.

Concrete contractors have adjusted to the use of vapor barriers by adjusting their mixes, adding a little more reinforcement at the bottom of the slab, and using well-graded, compacted aggregate below the slab. In general lowering the water content and water-cement ratio will solve most of the finishing problems.

One last thing: Before insulating any basement, make sure there are no basement water problems. In many cases, water problems can be solved by better management of rainwater with gutters and downspouts that direct water away from the foundation. In new construction, it’s also important to place a durable vapor barrier directly beneath the slab.

Read More on Basement Vapor Barriers Foundation Insulation Coatings

DAN b says

Most Cost-Effective Way Tp Cover Foam on Foundation

Our new build basement uses FOX BLOCK poured walls. Our Village code is requiring us to cover the walls. We would like to know what the most cost effective way would be to cover these walls. Is paneling the cheapest way to cover the walls? Seems like Paneling would be easier then planks, etc. We look forward to hearing from you.

buildingadvisor says

Fox Block uses expanded polystyrene foam (EPF), which needs to be covered for both fire protection and to protect the foam from physical damage. Exposed foundation areas seem to get more than their share of dings from errant baseballs, lawn mowers, and other yard activities.

There is no consensus and the “best” or most “cost-effective” way” to cover and protect the foam. In my experience, the most common approach is some form of “parging” — that is, painting or troweling on mortar or a cementitious coating, including proprietary products sold for this purpose. If you use a good quality acrylic-modified mortar and apply it over a reinforcing steel mesh, then you should end up with a pretty durable finish at a reasonable price. Also, this type of finish is easy to repair if an errant baseball or lawnmower were to smash into it.

Panel products, like you mention, are also widely used — either standard products such PT plywood or fiber-cement products such as Hardie’s trim panels, which come in various widths. Proprietary products made from a variety of products are also sold for this application.

My preference is to use off-the-shelf products, which are usually cheaper, and will be easy to find a year or two later if repairs are needed. The final appearance will depend on the treatment at seams and corners, and whether any finish is applied for aesthetic reasons. For example, a textured gray paint will make the plywood look more like a cement product.

None of these approaches is very expensive, especially if you are doing the work yourself. Which will work best depends on your level of skill, the application technique, and the expected degree or wear and tear. Panel products tend to be more durable, but mortar over stucco mesh can be pretty tough and easy to touch up the dings.

Read more about {Protecting Exterior Foam

JW says

Should We Cover Block Wall With Poly Before Insulating?

I live in Minnesota and had a contractor that placed plastic on concrete block basement walls then framed and added paper faced insulation.

Is this bad to do? I have not hung sheet rock as of yet. I smell something coming form basement not sure if it is mildew smell or a dead mouse but it is concerning me that the plastic should not be there? Your thoughts?

Thank you

buildingadvisor says

Our preferred technique for insulating block and concrete foundations, once any moisture problems are resolved, is to insulate with rigid foam insulation placed directly against the block or concrete. This approach has far fewer problems than insulating fiberglass in a framed wall as you have done.

The foamboard should be well-sealed against air and moisture at all joints and edges. On the interior side of the foam, you can install drywall or any other wall covering that will allow some moisture transfer — not polyethylene or other plastic sheeting.

You can put studs and unfaced fiberglass batts on the inside of the foamboard if you want additional insulation and a place to run pipes and wires. But, again, you do not want a wall finish that will block vapor. This allows the wall to dry to the building interior as needed.

Placing moisture sealers or poly sheeting against the block wall before insulating is generally not necessary, but usually causes no harm. Any moisture or leakage problems need to be addressed on the exterior side of the wall before insulating.

Not sure what is the source of the odor you are smelling. Moisture trapped on the exterior side of the poly will not harm the block wall or cause mold. It’s possible that mold is growing within the framed wall — for example, of the bottom plate if it is sitting on damp concrete.

I would suggest tearing off and discarding the paper facing. I will do more harm than good in this type of wall. If you can pinpoint the source of the smell, pull out the insulation to inspect the framing and insulation for mold.

Let the assembly dry out thoroughly. If you have well-drained and dry block wall, and the framing and insulation is odor-free, you can install the drywall and hope for the best. You might be fine, or you might develop moisture problems in the wall.

If you want the most resilient wall, start over with foam insulation as described in the article above.

Read More about Basement Vapor Barriers

JW says

Hello Steve

Wow, thanks for your quick reply. I just took down a few pieces of insulation and cut the plastic out.

The plastic is the source of odor it seems , also a little bit of brown color was in the batting of the insulation that is in front of the plastic.

Why is the paper faced insulation a possible cause of a problem?

buildingadvisor says

Most foundations are a little bit wet to very wet – after all, they are made out of very porous materials (concrete and masonry) which are buried in soil — which is usually pretty moist (except in very arid climates). The air within the soil is usually saturated with water vapor.

So it’s no surprise that most basements are musty and moldy to some extent. When you insulate and finish a basement, you will be compounding any moisture problems that already exist. So it is highly recommended that you get the foundation walls as dry as possible before insulating.

The main strategies for accomplishing this are

exterior drainage (to get surface water away from the house)

gravel backfill or synthetic drainage mat against the exterior side of the foundation wall (to keep moist soil away from the masonry)

footing drains (to get subsurface water away from the house)

waterproofing or dampproofing on the exterior side of the foundation wall to prevent moisture transfer and leakage

The exact configuration will depend on specific site conditions, usage plans for the space, and your budget.

Because the soil is almost always more humid than the air in your basement and house, moisture is always trying to migrate into the house. Despite your best efforts, some will get it either as liquid water or water vapor. The moisture should be allowed to dry inward toward the room. That means no moisture barrier on the interior side of the finished basement wall.

Poly sheeting is impervious to moisture, so it should never be used on the interior side of a finished basement wall. But Kraft paper facing is also a pretty effective vapor retarder. So it can also trap moisture in the wall cavity – especially with poly against the wall as in your case. The moisture is now trapped between two vapor barriers.

So removing the paper facing may solve your problem. If it doesn’t, then you may need to remove the fiberglass as discussed in my first email and insulate with foam board. Then you can reuse the framing and fiberglass on the interior side of the foam – so it will not go to waste.

Richard OLoughlin says

Does It Make Sense To Insulate Just Part of a Basement Wall?

I’d like to insulate the basement and have read everything here. I have mechanicals in three different spots. We’re on a well so I have the pump tank as well as water conditioning. Allowing for a little service space left and right there’s 8 feet of wall that would be left as bare concrete. (I may be able to sneak in 1 inch insulation board behind 4 feet at inches (I” XPS and 1/2 inch fire rated dry wall would be tight. Very tight. In order to get the entire 8 feet would require replumbing by the well company and the water conditioning company. Next we have an on demand water heater hanging on the wall. The unit, gas lines and plumbing is such that there would be 6 feet of bare concrete. Lastly is the electric panel. It was built as stood off so I’d be able to insulate about 80% of the 4 feet. So here I’m faced with three sections of lower performing or bare concrete. The overall basement dimensions are 58×28. I understand I’ll get SOMETHING out of insulating but I’m wondering with these large gaps is it worth it? By the way, it would be 2 inch XPS with a wall and insulation as well.

buildingadvisor says

Heat loss by conduction (through a wall, door, or window, for example) is additive. So, in theory at least, insulating 80% of the wall will provide 80% of the benefit of insulating the entire wall. So do the best you can on the areas that are accessible.

A good example is a room with large windows. The walls might be R-25, but the windows are closer to R-3. You can still stay warm in the room, as the overall rate of heat loss is manageable by the heating system.

Also keep in mind that heat loss is greatest near the top of basement wall where it is exposed to the cold outdoor air. The heat loss is proportional to the temperature difference between indoors and outdoors. Six to eight feet down, the earth has a stable temperature of about 50F, so heat loss there is minimal. So he more you can insulated the upper half of the wall the better.

Another point to keep in mind is that the first little bit of insulation yields the greatest savings (law of diminishing returns). So increasing your R-1 foundation wall to R-2 cuts the heat loss through that section of wall by 50%. Doubling to R-4 cuts the heat loss by 50% again. But each 50% savings is half as big as the prior one. At some point, it is no longer economical to add more insulation. So if you can squeeze in an inch of foam, go for it. I you are not able to cover it, many building inspectors will allow foil-faced insulation to remain uncovered by drywall.

Adding a little insulation also helps a lot with the “radiant temperature.” That explains the feeling of cold you experience when standing near a very cold surface, regardless of the air temperature — or the warmth you feel near a warm surface or in the sunshine. In this case you are heating the cold wall with your body by infrared radiation or the sun is heating you by infrared. Adding all the radiant exchanges in a room provides the “mean radiant temperature” that you experience.

So do the best you can with insulation. Also consider boxing the utilities into a separate area, making sure that it stays warm enough to prevent freezing.

Mike P says

Do I Need To Cover Foam Board on Basement Interior

I am placing 2-inch-thick foam board insulation on the inside of the basement walls. I am told I still will need to cover it or protect it. Why is this necessary on the interior? What would I have to use to cover it?

buildingadvisor says

Fire codes generally require that most type of foam boards be covered on the interior with a 30-minute fire barrier such as standard 1/2-in. drywall. Local codes may require thicker drywall or fire-rated drywall for some applications.

One exception is foil-faced foam board. Some local codes allow this material to remain uncovered with the foil acting as the fire barrier. Always be to check with you local department of building inspection as local code officials have the final say.

James says

Can I Insulate A Frame Wall on Interior Side of Foamboard?

Fantastic information thank you.

Looking to interior insulate a 60-year old concrete block basement. Most of the walls are perfect but there is some efflorescence in spots, but for the age of the walls not terrible in my opinion. There is zero liquid water issues through the walls or floor. Summer humidity is easily kept in check with a small dehumidifier, and there is a sub-slab radon system.

Should I be good to go with directly attaching XPS foam boards to the block as detailed here? I would likely also frame out walls and add additional Roxul before sheetrock.

If so, is there any consideration of using a more permeable (1”) foam board vs. a 2” board to allow the wall and structure to breath more/less?

Thanks!

buildingadvisor says

All sounds good. The XPS foam is against the concrete as it should be. Any moisture between the foam and wall will not hurt the foam or the concrete. You want a low-permeable board here to keep any moisture on the concrete side of the foam. Seal the foam at seams with contractor’s tape and around the perimeter with spray foam. Also insulate and seal the band joist area.

Your wood-frame wall is on the interior side of the foam, as it should be. You can use any type of insulation there — Roxul or fiberglass would be my first choices. Use unfaced batts and don’t use any poly sheeting or low-perm vapor barrier on the interior, just painted drywall.

You want the insulated stud spaces to be able to dry to the interior, should they ever get wet for any reason.

Run the dehumidifier as needed. An added benefit of sub-slab radon systems is that they also dehumidify the basement by removing moist air from under your slab, which helps keep the basement dry. So, yes, it sounds like you’re good to go.

Rob says

Best Way To Float Subfloor Over Slab?

What are your thoughts about using a single layer of 3/4″ subfloor like Advantech (moisture resistant) over 2″ XPS and floating it rather than using 2 layers of 1/2 plywood fastened?

buildingadvisor says

Not sure what you are using for finished flooring. In general, however, if you are floating the subfloor over concrete, you are much better off with two layers of plywood or other panel products (like Advantech). The two layers should have all seams offset and be and screwed together or nailed with ring-shank subflooring nails. Be careful not to puncture the vapor barrier, if it’s placed on top of the foam. For extra security, you can also glue to two layers together with a compatible construction adhesive — or yellow carpenter’s glue.

The top layer of subfloor should run perpendicular to the bottom layer, or at 45%, as shown in the illustration below (from my book, Best Practices Guide to Residential Construction).

Whether you use plywood or Advantech, make sure you follow the manufacturer’s instructions for spacing at seams and around the perimeter as some seasonal movement can be expected. Advantech manufacturer Huber shows a detail at this link.

Also make sure the slab is dry before proceeding. As a quick test, you can duct-tape a 24 x24 -in. piece of polyethylene to the slab and see if water beads up under the poly after 24 hours. This is not a definitive test, but will indicate if the there is significant moisture coming from the slab.

If you have a gravel layer (capillary break) and poly under the slab, you may not need a poly vapor barrier on top of the slab. But it doesn’t hurt.

Rob says

Thanks for the info here Steve, I really appreciate the feedback. I’ll probably just be putting laminate down on top of the subfloor. I was hoping, since the Advantec is T&G and pretty heavy, it would be enough to avoid a second layer. I have 2” of foam already and hate to lose another 3/4 inch doubling up. That would bring me up 3.5” without the laminate! Also, $60 a sheet for the Advantec, turns me away from this option. Can I just use normal 1/2” sheathing and fasten the two layers as you outline?

buildingadvisor says

Yes, headroom is always an issue. For laminate flooring, two layers of ½-inch plywood should be fine. For the top layer, I would use a plywood rated for underlayment use, which means that it has at least one sanded face with no voids or irregularities in the surface.

If you cannot find a product rated for subflooring, use an A-C or B-C plywood with the good face up. Whatever you use, inspect the surface and edges for voids.

For the bottom layer, you can prob1ably use a lower grade plywood such as C-D. Some CDX might be acceptable, depending on the supplier. Like many things, plywood quality has deteriorated over the years, so it may be worthwhile paying a little more for better material at a contractor yard vs. a DIY home center.

Tom says

Interior vs. Exterior Insulation For Extreme Cold

I’m in IECC climate zone 8, and the ground sometimes freezes as far as eight feet down in the winter. Is it really okay to expose the foundation to repeated freeze and thaw cycles, by insulating the basement on the inside?

buildingadvisor says

I can say with confidence that interior insulation works fine in Zone 6 where I live. But I don’t have a lot of experience building in extremely cold climates like yours. Zone 8 is considered sub-tundra, so special building details are required.

Most concrete problems with freeze-thaw cycling are related to moisture getting into the surface of the concrete, expanding when it freezes, and causing spalling or other types of surface cracking and deterioration.

The usual solutions involve good drainage, strong concrete mixes, concrete sealers (silane/siloxane), and sometimes air-entrainment in the concrete. All things being equal, I agree with you that it is less risky to insulate concrete foundations on the exterior in your climate as it will reduce both the exposure to moisture and the amount of freeze-thaw cycling.

Also, good foundation drainage and waterproofing will go a long way toward preventing foundation problems.

Always a good idea to check with some local foundation contractors about what has worked best for them. They have real-world experience and some skin in the game.

Erik Wohlfarth says

Best Insulation for Basement Retrofit?

What’s considered best practice for insulting and finishing retrofit cmu basement in northeast? The existing finished basement is 1×3 furring 16″oc with wood paneling. The basement does get humid and musty and dehumidifiers work well to address this problem, the structure elevation and surrounding ground perks well and there’s little to no hydrostatic water infiltration. There’s no floor drains, an old sump pit/inoperable pump used for retro radon system. There’s washer/dryer and washer discharge is pumped via the washer up to kitchen drain line. The basement is partitioned with cmu bearing wall and stud walls with gyp board and paneling. The large family room is the focus of the retro L config with 3 ext fnd walls w furring and paneling, 1 ext fnd w parging, 1 int cmu bearing wall w furring and paneling, 1 int stud wall with gyp and parging🤓 What’s your suggestions for insulating and finishing the exterior walls? My thoughts are mixed and I’m uncertain if it’s best to leave the exist 1×3 furring and use 3/4 foil faced polyiso (foil facing cmu for moisture barrier?) between and apply another 1-2″ of rigid foam (without foil faced polyiso another type?) and apply mr gyp board? I’m not adding studs and batts for fear of condensation and mold and preserving square footage. What are your thoughts? Thanks

buildingadvisor says

Best practice for interior basement insulation in New England is foam insulation placed directly against the basement wall. The panels are help in place by adhesive or mechanical fasteners such as plastic masonry anchors or Tapcons (for thicker panels). Most building codes require or recommend a minimum of R-10, while some energy experts would prefer to see R-15 to R-20.

While some energy experts recommend a semi-permeable foam such as XPS or EPS, many builders have used foil-faced polyiso without problems. The concern is that XPS and EPS allow some drying to occur towards the interior of the space. But since concrete and CMUs are unaffected by moisture, drying to the interior should not be a concern. That’s one reason to attach the foam directly to the walls, without framing or furring which could hold moisture and grow mold.

The important detail is to make seal the foam layer to keep interior air from reaching the cold basement wall, where it is likely to condense. Use a high-quality contractor’s tape to seal the seams and spray foam to seal around the perimeter of the foam. You can add furring or studs on the inside of the foam for wiring and nailing for the drywall. Another option is to glue the drywall directly to the foam and use surface wiring.

Of course, before finishing the basement, make sure that any moisture problems are addressed. It sounds the existing finished basement is a bit musty. That could be due to the traditional approach of fiberglass insulation in a stud wall with a vapor barrier, but also could indicate that the site drainage and/or foundation drainage needs to be upgraded. You also mentioned a retro radon system. Is it still operational? In addition to controlling radon exposure, these generally do a good job of reducing basement moisture levels.

MR drywall is a good idea, but you might also consider upgrading to one of the newer mold-resistant gypsum products that are gradually replacing traditional “greenboard.” These combine the wax-paper treatment of MR drywall with mold-resistant additives.

James says

What Are Foam Strips Aside Basement Windows?

I have a block foundation and need to get the parging re-done. While inspecting, I noticed that each basement window has what appears to be foam insulating on either side of the window running from the ground to the top of the window and about 3-4” wide.

Any idea what I’m dealing with? Parts of it are damaged and I’m worried about insects. Wondering what I might find if I take it down.

buildingadvisor says

Various types of foam and concrete (or block) sandwiches have been used over the years in an attempt to build insulated concrete walls. THe most common are ICF’s (insulated concrete forms) where the foam forms are left in place after the concrete sets to provide insulation.

But I can’t think of any useful role for vertical strips of foam along the sides of the windows — unless they were part of a system to insulate the windows in cold weather.

The foam strips won’t provide an measurable insulation, but can provide homes for carpenter ants and hidden pathways for subterranean termites to travel from the ground to wood structure undetected.

So I see no reason to keep the foam in place before parging.

Brandon Pelzer says

Should I Add 6-mil Poly To Foam Board Before Backfilling?

I am currently building in Minnesota. I am putting 2 inch foam board on the exterior of basement foundation. Should I put 6 mm poly between the foam board and the backfill?

buildingadvisor says

In most cases, granular backfill is placed directly against the foam without any problem — as long as the foam is secured well against the basement wall and the backfill is placed with reasonable care.

To keep the foam in place before backfilling, contractors generally use a construction adhesive that is compatible with foam board, or mechanical fasteners (or both). Hilti makes a couple of nail-on plastic fasteners that are easy to install in 3/16 holes drilled in the concrete with a hammer drill. One fastener at each corner of the foam board and one in the middle is usually sufficient.

Adding a layer of 6-mil poly may be overkill, but shouldn’t cause any problems. If you are concerned about drainage, a layer of dimpled drainage mat over the foam will provide good drainage down to the footing drains and help protect the rigid foam from damage.

Mike Thompson says

In my application, I used exterior XPS to insulate the basement when constructing our house 40 years ago. We used 2” foam down 6-8 ft. and protected the foam with a parging material from Dow that goes over a mesh. The exterior foam insulation tapers back to a termite shield and the exterior is ground-treated for termites. No problem with damage to the parging as we have a planting area all around the foundation (see photo).

Our house uses passive solar heating. A somewhat unique feature is we use the full basement as a return air plenum with floor vents for a return. I think insulating the exterior and using the whole basement as a return has many benefits:

1. The basement is moderately heated and cooled just utilizing the return air. The basement slab floor, 8 ft. below grade, provides a year round source of 56 degree F energy. This is typically warmer than outside in the winter and cooler than the outside in the summer, so exhibits passive heating and cooling characteristics

2. The heat sink mass of the house is greater, providing a day or two transition to changing outside conditions.

3. The basement walls are easily finished with paint.

4. A termite shield and an inspection gap have been effective.

5. There is no need of a supplemental dehumidifier as the whole house AC unit provides that function.

6. The presence of basement mold is reduced since there are no pockets of cooler surfaces without somewhat year round ventilation.

In short, we have found the combination of the exterior basement insulation and using the full basement as a return plenum effective and efficient.

buildingadvisor says

Interesting use of your basement as thermal mass. There has been a lot of debate about whether keeping the thermal mass inside the basement insulation reduces energy costs. Researchers have determined that, in a conventional homes, it doesn’t matter whether the thermal mass is inside or outside the insulation. Heating and cooling costs are about the same.

One exception is high-mass walls in very sunny climates with large daily temperature swings, like an adobe house in Santa Fe. The mass tends to smooth out the daily temperature swings that would otherwise make the house too hot during the day and too cold at night. In a climate that is consistently cold in the winter, like New England, high-mass walls can make it hard to heat the house after setting back the thermostat.

In a passive-solar home, the extra mass could help in houses with enough glass that the house overheats on sunny days. Most solar designers use a direct-storage solution like ceramic tile on a concrete slab that’s directly heated by sunshine. Getting the heat into and out of mass in a remote location, like the basement walls, is a trickier proposition. Also too much glass in a cloudy climate, can lead to high heat loss and discomfort on cloudy days. Getting the right balance of glass and mass takes expertise in solar design. Sounds like you got it right!

Robert says

Can I Cover Foundation Insulation By Raising the Grade?

My 1980s-era house foundation has several inches of sheet foam exposed at ground level, with aluminum flashing above (see photo). The foam is unsightly. Would it risk termites or other problems to raise up the ground level with soil or river rock so as to cover up the foam? Thanks.

buildingadvisor says

I’m not a big fan of exterior foam insulation on foundations for some of the reasons you mention. Most of the materials used to protect the foam eventually get damaged by lawn mowers, baseballs, or just wear and tear at the ground level.

Also, the foam provides a perfect entry point for subterranean termites, which can tunnel behind or through the foam to reach the wood framing above.

The minimum clearance from grade to any non-treated wood (framing, sheathing, or siding) in the International Residential Code is 6 in. although state codes may differ. I like to see 8 in. There is some debate over whether you can less clearance to paved surfaces such as concrete or asphalt. You can view the detail at this link.

One of the issues is having an inspection area for termite mud tubes leading from the soil to wood framing along the outside of the foundation. With exterior foam in termite regions, this requires that a strip of insulation be removed where it is needed most above grade.

So, yes, you can raise the soil level on the exterior, but should still leave at least 6 inches of exposed foundation. If the aluminum flashing is unsightly, you can consider replacing it with a more durable material.

There is no perfect material for this application. Some contractors prefer a stucco finish applied over hardware cloth or stucco lath to give it greater strength. Stucco finishes applied directly to the foam are not very durable.

Other contractors prefer panel products such as cement board (such as James Hardie HardieBacker) or pressure-treated plywood. These can be finished with a durable stucco finish or exterior paint, depending on the appearance you want. Another durable, but high-cost, option is cultured stone veneer.

Whatever system you use to cover and protect the insulation, you still have a direct conduit for termites to move from the soil to the wood structure. Carpenter ants also like to excavate exterior insulation to create a

So if you are in a termite-prone area, you may want to consider moving the insulation to the interior side of the foundation wall. In any event, you should check first with a termite expert for an effective treatment strategy.

Mark Halls says

Can I Use Foil-Faced Foam on Basement Walls?

I am doing a basement renovation and have already purchased foil-faced EPS (SilverR board) for my continuous insulation barrier against my concrete foundation wall. I will then have 2×4 stud with Ruxol Comfort Batt.

I have read a lot of recommendations against using foil faced rigid board in a basement wall assembly but my question is why? If foil faced EPS is mold resistant and impermeable to moisture, and concrete can stay wet for its life then what is the harm of moisture present between those two materials? Won’t trapped moisture just evaporate over time?

Thanks for your time.

buildingadvisor says

The usual recommendation is for unfaced foam on the interior of a basement wall, sealed at joints and along the top and bottom. This creates an air barrier, keeping interior basement air away from the cool basement well where it may condense, and keeping moisture from the basement wall from entering the basement interior. Concrete is highly permeable to water vapor, so it tends to pass soil moisture into the building.

Foundations are complicated because moisture can move in either direction, depending on the soil conditions, dampproofing or waterproofing on the basement walls, and temperature and humidity of the interior air.

Unfaced EPS foam is fairly permeable to water vapor with a perm rating of 5 for 1 inch and 2.5 for two inches, making it a Class III vapor retarder similar to latex paint on drywall. Extruded polystyrene (XPS) has a perm rating on 1.1 for 1 inch and .55 for two inches making it a Class II vapor retarder similar to kraft paper (for a 2-inch board).

Foil facing, however, makes any foam board virtually impermeable to water vapor like polyethylene. These are considered Class I vapor barriers.

Using an unfaced foam insulation is hedging your bets, allowing for a minimal amount of drying, in either direction, should things get wet for any reason. Using foil faced insulation could potentially trap liquid water between the foam and foundation wall. However, if there is no wood between the foam and the wall, you are correct that there is no harm to the concrete. Maybe the foil facing could delaminate depending on the adhesive used, but no great harm there.

So, bottom line: I wouldn’t worry about installing foil-faced EPS insulation directly against the basement wall the way your describing. However, it would be a good idea to seal the joints between panels and the perimeter of the insulation to keep the interior air basement air isolated from the basement wall.

Donald says

XPS vs. EPS Foam For Foundation Insulation

Which do you recommend if price is not a problem? XPS or EPS?

Separately, my contractor is recommending roxul insulation over foam board? They said roxul is moisture resistant and they use it in every basement remodel.

buildingadvisor says

On the interior, either is fine. XPS provides about R-5 per inch vs. R-4 per inch for EPS, commonly known as beadboard. So you can pack more R-value in a smaller space with XPS.

On the exterior, I would definitely go with XPS, which has a higher compressive strength, less water absorption, and greater durability. Exterior foundation insulation takes a beating during installing, backfilling, and settlement of the soil. Also the portion of the insulation above-grade gets a lot of abuse regardless of the finish used.

Beadboard gets its name from the tiny beads that are fused together and tend to bread apart under stress. XPS holds up better under real-life conditions.

Either material is easily excavated by carpenter ants, however, for warm housing in the winter – one of the reasons I prefer insulating basements on the interior.

Roxul is another option for interior basement insulation. It’s true that it is impervious to moisture and insect damage as is unfaced fiberglass. However either one can trap moisture if there is condensation in the wall cavity or moisture migration from the exterior. Remember, a foundation wall with interior insulation is colder than an uninsulated wall, so condensation is more likely to occur in warm weather.

So I’d stick with a layer of foam against the concrete. Then you can add Roxul or unfaced fiberglass between the studs for extra insulation. Whatever you do, don’t put a poly vapor barrier anywhere in the wall.

Donald says

Given the risk of foamboard and excavation by carpenter ants which I do not want to experience, would another alternative be to go with the roxul comfortboard directly on the basement concrete wall? Given the moisture resistance properties of Roxul comfortboard, there should be a lesser chance of trapping water compared to fiberglass and mold building up.

Happy to hear your thoughts

buildingadvisor says

Yes, you can certainly use Roxul Comfortboard, placed directly on the interior side of the basement wall. Comfortboard’s main use is for exterior insulation, but there’s no reason why it will not work as well on the interior.

I’ve not heard of carpenter ants getting into interior foam on a basement wall, but it is certainly possible, especially in wooded areas or other places with ant problems. If you add a stud wall inside the Comfortboard, you can fill the cavities with unfaced fiberglass, rock wool, or any water-resistant insulation for additional R-value.

Depending on your climate, a 1 to 1.5 in. layer of Roxul Comfortboard (R 4/in), should keep the interior surface of the board warm enough to prevent condensation in warm weather.

The interior surface of the insulation board is the condensation plane for warm, moist air in hot, humid weather.

Marlowe says

Basement Insulation For A Tight Space

Building a basement in Colorado. The space it really compact and I would like to add some rigid foam to help with the cold weather but i don’t want to lose any interior square footage i don’t have to. Can i use 1/2″ rigid foam and some unfaced batts? or is this a terrible idea?

buildingadvisor says

The best way to preserve square footage on the interior is to use exterior insulation. The main problems are that bugs like to burrow in and under the foam, and the portion of the foam above grade needs protection from the elements.

Mineral wool boards such as Roxul Comfortboard is a great option for exterior foundation insulation as it fire-, bug-, and mold-resistant. It has an R-value of R-4 per in. – in between EPS foam and XPS foam, the other main alternatives.

If you’d rather insulate on the interior, and want to save space, why use fiberglass insulation, which only provides about R-2.5 per in.? Foil-faced polyiso board (Polyisocyanurate) will give the highest R-value at about R-6 per inch. In some areas, code allows to leave the foil-facing exposed – not the case with polystyrene, which must be covered by a fire-rated material. However, since you intend to finish the space, this shouldn’t be a problem either way.

I’d recommend two inches of foam board, with vertical or horizontal strapping on the interior as nailers for the interior finish. The 3/4-in. air space will get you a little extra R-value with the foil facing as well.

Avraham says

Should I Put Vapor Barrier on Basement Wall?

I am finishing a basement in Brooklyn, new york. I am confused as to whether I need a vapor barrier, a moisture barrier, or no barrier at all? Also how much insulation is enough, if needed at all? Thank you

Also, can I tile directly to the concrete floor? Is there any way to insulate the floor?

buildingadvisor says

The short answer is no, you generally do not want a vapor barrier on the walls of a finished basement.

The place to control vapor migration is on the exterior of the basement wall, in the form of waterproofing or damproofing.

On the interior, the best insulation to place against the concrete or block is rigid foam without any facing, such as foil or plastic sheeting. This allows for some drying to take place as foam board is somewhat permeable.

The recommended minimum is R-10 for your area, which you can achieve with two inches of extruded polystyrene (such as Dow Blueboard) or 2-1/2 inches of beadboard. Seal all joints with foam sealant to keep moist interior air from reaching the cool concrete wall where water will condense.

If you are placing a stud wall against the foam, it’s cost-effective to add unfaced fiberglass batts between the studs. You can also use flat 1×3 furring instead of studs to save space, but without the added insulation. Finally, you install the drywall and paint with a standard latex paint.

In addition to saving energy, the space will be more comfortable and dryer when insulated and finished.

The goal is to create a wall that is somewhat permeable to water vapor, so drying to the interior can take place when needed. Moisture can collect on the basement wall either from the interior (condensation) or exterior (moisture transmission from the soil). Allowing the moisture to escape helps protect the wall system from mold and moisture damage.

If your basement has any moisture problems, these need to be solved before insulating. Otherwise, you’re asking for trouble by trapping excess moisture inside the wall system.

Read more on Basement Vapor Barriers

Regarding your second question about installing tiles over the concrete slab, there are several ways to do this. You can apply tile directly to a concrete slab with thinset, as long as the slab is level, clean and stable. If the slab is uneven or out of level, you can add a lightweight cement leveling compound to the surface before tiling.

Use a leveling compound approved as a tile substrate. An “isolation membrane” is highly recommended directly under to tile to protect it from any cracking or motion in the underlying concrete slab.

If you want to insulate the floor, you can use 1 to 2 inches of extruded polystyrene, fit between pressure-treated 2×4 sleepers. Screw ¾ inch plywood subflooring to the sleepers, and then screw another layer of plywood underlayment (min. ½ in.) or tile backerboard to the first layer of plywood. If you use two layers of plywood, adding waterproof carpenters glue between the two layers of plywood will provide a very strong and stable tile base.

Offset the joints between the two layers of plywood (or plywood and tile backer) and screw the top layer only to the subflooring, not into the sleepers. Next install your isolation membrane (which can also serve as a waterproof membrane as needed). Finally install the tile with thinset mortar.

I would not recommend the tile work as a DIY job unless you’ve got a fair amount of experience with tile.

Beth says

Insulation & Vapor Barrier Under Basement Floor?

We are in the process of building in Maine. The walls of the foundation were poured last week and they will backfill on Monday, 9/17/18. We plan to insulate the inside walls of the basement with at least the R10 foam board. They put the black tar stuff painted on the outside. We plan to have gutters and they are digging trenches to divert water away from the house that the gutters will work with.

The one thing that our builder has not mentioned is putting any type of foam board in the floor of our basement. Also, you said above, during new construction its important “to place a durable vapor barrier below the slab.” What is recommended?

buildingadvisor says

Because deep-earth temperatures remain pretty constant, at about 50-60ºF, insulating under the basement floor will not save you much money, unless you plan to heat the space and use it as living area. However, insulation under the basement slab will help reduce condensation on the basement floor in warm weather, reducing musty odors and damage to floor finishes. You can read more here on Subslab Insulation.

Whether or not you insulate under the basement slab, a sub-slab vapor barrier is a good idea. It needs to be “durable” to survive the process of placing and finishing the concrete. Special reinforced polyethylene, designed for this application, is available from several manufacturers. Products include Stego Wrap, Perminator, and Viper. In general, sub-slab vapor barriers should be at least 10-mils thick. Read more here on Subslab Vapor Barriers.

The “black tar stuff” they brushed onto the outside of you foundation is called “dampproofing”. This cuts down on water vapor transmission from the soil through the foundation wall into the basement. It is not waterproofing, however. If you are considering finishing areas below grade to use as living space, you should consider a full waterproofing system, if it’s not too late (before they backfill). You can read more here on Basement Waterproofing.

Mike says

Underslab Insulation Down South?

I’m building a house in Burnet, TX, in the Texas Hill coutry. I like the idea of putting 2 inches of foam board under the slab to keep cold from coming up from the ground in winter months. Is this a good idea to thwart thermal bridging to the ground?

buildingadvisor says

Most people in your part of the world do not insulate slabs-on-grade and are not required to by code. Your county is in DOE Climate Zone 3, just over the line from the warmer Climate Zone 2. Slab foundations in the colder Zones 4, 5, and 6 are required to have insulation around the slab perimeter under the IRC. Additional subslab insulation is recommended in those locations.

by energy experts.

In your area, you would get some benefit from slab insulation around the perimeter of the slab where a slab’s heat loss is greatest. Two inches of vertical perimeter insulation will keep the outer portions of the floor warmer in winter, increasing your comfort and modestly reducing heating bills.

You could also add 2 inches of horizontal underslab insulation in your area. This would keep the slab a little warmer in summer, reducing condensation on the cool floor, but also raising the air conditioning load a little, so it is a trade-off. Because the energy benefits are questionable, most people do not install underslab insulation in warm and hot climates.

You can see the energy benefits of these configurations in Table 4.1 from the US DOE Builder’s Foundation Handbook.

In a monolithic slab, the perimeter insulation needs to go on the exterior of the foundation, and will need protection from UV and physical damage (see pic). In a slab with a stem wall, the insulation can go on either the interior or exterior of the stem wall. While it is possible to add horizontal insulation under a monolithic slab, it is tricky to accomplish and not commonly done.

With an insulated slab, you need to consider termite entry. In addition to soil treatment, you may need a termite shield so you don’t provide a hidden entry path behind the foam and into your structure. Requirements vary with state and local codes so check first before proceeding.

For insulation, the most common choice is XPS (extruded polystyrene), but high-density EPS rated for ground contact can also be used. You can expect to lose 30% to 40% of the insulation value over time from water absorption by the insulation. A newer option is Roxul insulation board made from mineral wool. It is a very good option for vertical applications as it is self-draining, and may also be suitable for underslab insulation – but check with your local code official before using it under a slab.

You can view these and many more foundation insualtion details at the new, online version of the DOE Builder’s Foundation Handbook at this link.