Q: We recently purchased a property that has an old detached garage on it. Water is leaking into the garage all around the perimeter at the bottom of the wall (first photo). The garage is slab-on-grade construction with a 12-in.-high concrete stem wall placed on top of the slab. The problem is that the slab extends 6 in. beyond the stem wall, forming a horizontal skirt around the exterior of the garage (second photo).

We live in Western Washington where we get a ton of rain. Due to this design, the rain hits the wall, drips down onto the 6 in. skirt and then seeps into the garage where the stem wall joins the slab. (The stem wall was a separate pour of concrete from the slab and the water comes in at various points around the garage).

As none of this is below grade, I can find no guidance on how to waterproof this seam and would love some help. We believe this garage was built pre-1940’s on an old farm. — Chris H.

A: Your theory that the water is leaking in at the bottom of the stem wall is the most likely explanation. The way they built your slab and wall is unusual and almost guaranties a leak where the concrete stem wall sits on the slab.

In modern construction, the slab does not extend past the bottom of the stem wall. Either the slab sits inside the stem wall, or with a monolithic slab, the bottom wall plate sits along the edge of the slab with the sheathing or siding preventing water entry.

This leak could have been easily prevented by using a concrete bonding agent at the bottom of the stem wall when they poured the concrete. But it’s too late for that approach.

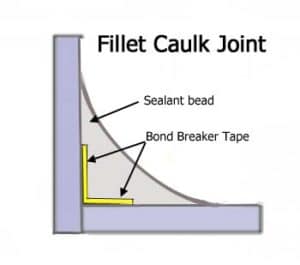

At this point, you will have to seal the crack in the corner where the stem wall meets the slab. Sealing this type of right-angle joint with a triangular bead of sealant is called a fillet seal – a difficult job for most sealants (see pic).

The most effective place to seal a water leak is always on the exterior, but if that is not practical, you could try the interior side of the joint. Because the leak is above grade, without hydrostatic pressure, an inside seal might work, but it’s not ideal.

You will need to clean and dry the joint before attempting to seal it. On the exterior, that would probably require pressure washing. Then use a stiff wire brush and vacuum to remove any residue. On the interior, a hose or sponge would probably work, followed by the wire brush.

Then you will need a high-grade, flexible sealant formulated for use with concrete. Avoid concrete sealants that are “self-leveling” as these will not hold the shape you want. Look for a non-sag sealant, that says it is suitable for vertical control joints.

My first choice would be a urethane sealant, such as Sikaflex Concrete Fix or Loctite PL-S10 Concrete Crack Sealant. You can get these at most lumberyards and home centers, but I would not buy online as urethane sealants have a limited shelf life. If you absolutely can’t get the joint dry, you could try a product like Sikaflex Construction Sealant formulated for use with wet concrete.

If you can get the joint reasonably clean and dry before sealing, you should be good to go. — Steve Bliss, BuildingAdvisor.com

Leave a Reply